BMW 335d Engine Common Problems and Fixes – Comprehensive Guide

Common Problems of the BMW 3 Series 335d Engine: A Comprehensive Guide

The BMW 335d sits at the top of the BMW 3 Series diesel range. Its BMW 335d engine uses a 3-litre straight‑six with sequential turbochargers that deliver huge torque and strong fuel economy. BMW fitted the first BMW engines for the 335d in the E90/E91/E92 models with the tough M57 block; later F30 and F31 models gained the N57 engine. Both engines offer over 300 horsepower and around 465 lb-ft of torque, yet owners often encounter problems as the cars age. Understanding these issues helps maintain performance and drivability, protects the engine and ensures that the vehicle’s handling and safety are not compromised. This guide discusses 335d common issues such as diesel particulate filter (DPF) blockage, exhaust gas recirculation (EGR) valve clogging, swirl flap failure and turbo or injector problems. It also examines the technical specification and history of the 335d engine and provides answers to frequently asked questions.

Technical Overview – What makes the BMW 3 Series 335d engine special?

BMW introduced the 335d in the mid-2000s as a performance-oriented diesel in the 3 Series. The first generation (E90/E91/E92) uses the M57D30TU2 engine, a 3.0‑litre straight‑six common‑rail diesel with sequential twin turbos. M57 is a 3.0 L inline‑six with a cast iron block and aluminium head that produces 180–286 hp depending on turbo configuration and up to 428 lb‑ft of torque. Later F30/F31 335d models received the N57D30T1 engine, an aluminium 3.0‑litre straight‑six with twin turbochargers and DOHC valvetrain producing about 309 bhp and 630 Nm of torque at 1,500‑2,500 rpm. This engine uses a double overhead camshaft and 24 valves, with a compression ratio of 16.5:1 and common‑rail direct diesel injection. The F31 335d xDrive accelerates from 0 to 100 km/h in 4.9 seconds and reaches a top speed of 250 km/h.

Swirl Flap Failure

Swirl flaps are small butterfly valves in the intake manifold that improve fuel-air mixing at low engine speeds. Plastic swirl flaps were used in early BMW M57 engines, and they deteriorate over time. These flaps can wear and break away, potentially being sucked into the engine and causing catastrophic damage. Swirl valves sit in the inlet manifold and mix exhaust gas from the EGR system with fresh compressed air; soot and unburnt fuel deposit on the valves and clog them. Symptoms include rough idling, loss of power and increased fuel consumption. Preventative removal or replacement of the flaps is recommended. Many specialists offer swirl‑flap delete kits or upgraded metal flaps to prevent breakage. If the flaps are intact, cleaning the intake manifold during major service can restore the vehicle’s performance and fuel efficiency. Regular maintenance around 100k miles is advisable because clogged swirl flaps restrict airflow and affect the vehicle’s performance and drivability.

Diesel Particulate Filter (DPF) Issues

The DPF traps soot in the exhaust to meet emissions regulations. Wall‑flow DPFs remove 85% or more of soot and rely on periodic regeneration, where the engine runs hotter to burn off accumulated particles. Regeneration typically requires sustained higher‑speed driving; vehicles used for short trips may not reach the necessary exhaust temperature. If regeneration is interrupted and the driver ignores the warning light, the filter can clog and create back pressure that reduces power and fuel efficiency and may damage the turbocharger. To fix a clogged DPF, drivers should take the car on a long, steady run to allow regeneration. In severe cases, a professional cleaning or replacement is necessary. Many owners replace or clean the DPF during engine rebuilds. Regularly checking the DPF status via diagnostics and avoiding constant short journeys helps protect the system.

EGR Valve Problems

The EGR valve recirculates a portion of exhaust gas back into the intake to lower combustion temperatures and reduce NOx emissions. The EGR valve opens as the engine warms to cool combustion and limit harmful emissions. Over time, carbon deposits clog the valve, causing it to stick open or closed. A stuck‑open valve floods the engine with exhaust gas and limits oxygen, leading to rough idling and stalling. A stuck‑closed valve lets combustion temperatures rise and can cause knocking. Symptoms include reduced fuel economy, sluggish acceleration and a check‑engine light. The guide lists clogging as the most common cause and recommends cleaning the valve to restore proper function. Some 335d owners choose to delete or bypass the EGR system, but on-road cars should keep the system working to stay compliant. During servicing, cleaning the EGR valve and cooler will help resolve these issues and protect the engine.

Turbocharger And Injector Wear

Twin turbochargers deliver the 335d’s impressive torque. However, high mileage and oil contamination can cause turbo wear. Turbos eventually wear and may need rebuilding or replacement, and their remanufactured engines include compression-tested turbos. Common symptoms of turbo problems include loss of power, excessive smoke, whistling noises or a lack of boost. Replacing failing boost pressure converters or vacuum lines can also resolve sluggish power delivery. Injectors can become clogged or fail over time; the same source notes that they test and replace injectors to ensure good spray patterns. Bad injectors can cause misfires, rough running and increased fuel consumption. Professional diagnosis and balancing of injectors is essential because unbalanced injectors may cause piston damage and affect engine performance.

Fuel And Air System Problems

Fuel system and air‑intake issues often lead to engine stalling or hesitation. The most common reasons a BMW 335d stalls are issues in the fuel system or air intake system. A clogged fuel filter or failing fuel pump restricts fuel flow, causing poor performance. A dirty or malfunctioning mass‑air‑flow (MAF) sensor restricts airflow and causes rough idle, misfires and black smoke. Replacing a faulty MAF sensor restores correct fuel-air measurements and improves drivability. Keeping the air filter clean and using high-quality fuel helps prevent these issues. Regular maintenance schedules should include fuel filter changes and inspection of fuel lines for leaks. Many 335d engines exhibit these problems around 100k miles, so preventative service is important.

Oil Leaks And Gaskets

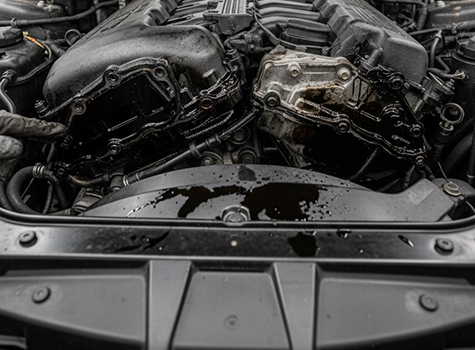

The M57 engine’s valve cover gasket and oil filter housing gasket are known leak points. Oil leaks as a routine issue, and notes that they replace these gaskets on remanufactured engines. An oil leak can lower the engine oil level and reduce lubrication, causing increased wear. Owners should monitor for oil spots under the car and inspect for oil residue near the valve cover and turbocharger. Replacing the valve cover gasket or oil filter housing gasket and using the correct torque settings will restore a proper seal. Failing to address leaks can cause smoke, smell and even engine damage.

Injector And Glow‑Plug System Faults

The M57 and N57 engines use piezo injectors and a glow‑plug controller. Faulty injectors can cause misfires, rough idle and poor fuel economy. The glow‑plug controller can fail and trigger a check‑engine light. Replacement of the controller and glow plugs resolves hard starting and improves combustion efficiency. Although many of these components last beyond 100k miles, regular diagnostics will identify weak injectors or glow plugs before they cause significant problems.

Suspension And Steering Issues

A strong engine is of little value if suspension and steering components are neglected. Worn control arm bushings and ball joints can cause vague steering, uneven tyre wear and poor ride quality. Although not an engine component, suspension wear can affect the vehicle’s handling and safety. Checking bushings, steering rack and power‑steering fluid will keep your BMW 335d stable on UK roads. On xDrive models, front suspension parts may wear faster due to additional weight. Regular inspection ensures the vehicle remains in top condition.

Preventive Maintenance And Remapping Considerations

Preventive maintenance is vital for longevity. Regular oil changes using the correct specification oil protect the turbocharger and timing chains, while coolant flushes prevent thermostat and radiator problems. Long motorway runs help the DPF regenerate. Cleaning or deleting swirl flaps, EGR, and DPF systems is a popular modification; however, UK emissions laws require these systems to remain functional on road vehicles. ECU remaps are common on the 335d. Remapping the M57 or N57 can unlock additional torque and horsepower thanks to their strong internals. Owners should only remap with reputable tuners and ensure that supporting hardware, such as intercoolers, transmission, and driveshafts, can handle the increased power. Ignoring supporting modifications can lead to transmission issues or drivetrain wear.

Frequently Asked Questions

1. What engine is in a BMW 335d?

Early E90/E91/E92 BMW 335d models use the M57D30TU2, a 3.0‑litre inline‑six diesel with sequential twin turbos producing around 286 hp and 580 Nm. North American models are slightly detuned at 265 hp and 425 lb‑ft. Later F30/F31 models use the N57D30T1, an aluminium 3.0‑litre twin‑turbo diesel generating roughly 309 bhp and 630 Nm.

2. Did BMW update the 335d engine?

Yes. BMW replaced the M57 engine with the N57 in 2013–2014. The newer N57 engine uses aluminium construction, updated injection and emissions systems and produces more power and torque while meeting stricter emission standards. The M57 remains admired for its simplicity and durability.

3. How many miles can a 335d engine last?

With proper maintenance, the M57 diesel can exceed 300,000 miles. Regular oil changes, fuel‑system care and timely replacement of swirl flaps, DPF and EGR components ensure longevity. The N57 is newer but has a similar reputation when well-maintained.

4. Is the BMW 335d engine Euro 6?

Most F30/F31 335d models built from late 2014 comply with Euro 6 emissions regulations, thanks to improved exhaust after‑treatment on the N57 engine. Earlier E90/E92 models meet Euro 4 or Euro 5. Always check the logbook and emission rating for your specific chassis.

5. What engine does the BMW 335d E92 have?

The E92 335d coupé uses the M57D30TU2 twin‑turbo inline‑six diesel producing around 286 hp and 580 Nm in European specification. In the UK, this engine provides strong mid-range torque and is paired with a six-speed automatic transmission.

6. What engine is in a 2007 BMW 335d M Sport?

The 2007 335d M Sport sedan or touring (E90/E91) also uses the M57D30TU2 twin-turbo diesel. Output in Europe is approximately 286 hp and 580 Nm, while US‑spec cars deliver 265 hp and 425 lb‑ft.

7. Will a BMW 335d engine fit in my 320d E90?

Physically installing a 335d engine into a 320d chassis would require extensive modifications, including wiring, fuel system, drivetrain and cooling upgrades. The 335d uses a heavier inline‑six and stronger transmission, so fitting it into a four-cylinder 320d shell is not practical. It is better to buy a 335d model or rebuild your existing 320d engine.

8. Is it the 335d twin turbo?

Yes. Both the M57D30TU2 and the N57D30T1 engines use sequential twin‑turbocharging. The NJ Global article notes that the M57 is available in single and twin‑turbo forms, and the twin‑turbo M57 variant powers the 335d. The N57D30T1 also uses twin variable‑geometry turbochargers.

9. Is it the 335d M57?

The E90/E91/E92 335d models use the M57 engine. The later F30/F31 335d uses the N57. When buying parts, check your chassis code to determine which engine your car has.

10. Is the M57 engine any good?

The M57 engine is widely regarded as one of BMW’s best diesels, delivering longevity, strong torque and fuel efficiency. It is capable of running over 300 k miles and is simple and reliable compared with more complex modern diesels. Enthusiasts appreciate its tuneability and durability, making it a favourite for performance builds and daily drivers.

READ MORE